OEM Contract Manufacturing Medical Devices – AMT Singapore.

Today, 60% of medical device firms rely on outsourcing to handle growing demand and speed up product launches. This trend has created opportunities in the Asia-Pacific. Here, AMT Singapore provides specialized OEM contract manufacturing for medical devices. They support developers scale their AMT’s OEM contract manufacturing medical devices operations swiftly while ensuring compliance.

AMT positions itself as a leading OEM medical device producer and partner for Singapore’s OEMs, R&D units, and procurement experts. Given market forecasts of $595–625 billion in the near term, outsourcing becomes indispensable to remain competitive.

AMT’s expertise includes precision injection molding, integration of PCBA and electronics, cleanroom assembly, quick prototyping, and strict regulatory compliance. Standards include ISO 9001, ISO 13485, and 21 CFR Part 820. This piece discusses how AMT operates in a sphere where giants like Jabil, Flex, and Sanmina have entered, while showcasing AMT’s specialized focus and grasp of the regional market’s nuances.

Highlight Reel

- AMT Singapore provides end-to-end OEM contract manufacturing medical devices by AMT for companies in Singapore and the Asia-Pacific.

- Growing global demand and market size make outsourcing to an OEM medical device manufacturer a smart move.

- AMT combines precision manufacturing, PCBA, cleanroom assembly, and rapid prototyping to support product scale-up.

- Regulatory compliance and quality systems are mapped to ISO 13485 and 21 CFR Part 820 requirements.

- AMT stacks up with global contract manufacturers by focusing on specialist OEM services and APAC responsiveness.

Why OEM Contract Manufacturing Matters in Singapore’s Medtech

In Singapore, the medtech sector is expanding quickly. Firms are under pressure to take products from lab to clinic quickly while preserving quality. To meet surging demand without significant investment, outsourcing production is a effective choice.

The push for market growth requires specialized skills and the ability to scale production. With global medtech expansion, there’s increased need for components such as PCBA, molded housings, and fluidics. Rapid innovation in cardiovascular and diabetes care increases complexity. To manage this, OEMs turn to outsourced manufacturing for access to state-of-the-art capabilities.

Outsourcing enables manufacturers to achieve precision without massive capital expenditure. Rather than investing in costly equipment and facilities, they partner with contract manufacturers that offer validated processes—reducing time-to-market and speeding regulatory approvals.

For Singapore-based OEMs, benefits include faster turnaround and regional support. Local contract manufacturers simplify logistics for ASEAN and APAC markets and support regulatory documentation for efficient market entry and compliance. OEM contract manufacturing medical devices by AMT can significantly streamline these processes via expert management.

Effective cost control and procurement expertise help minimize expenses. Contract manufacturers streamline tooling, sourcing, and supplier relationships to gain scale advantages—delivering more predictable, lower-risk rollouts so Singapore OEMs can focus on quality production without overextending resources.

Scalability and risk management are crucial. Outsourcing supports the journey from prototyping to full-scale production with validation at each step. Quality control, traceability, and compliance lower regulatory and supply-chain risks, aiding global expansion. Collaborating with reputable CMs empowers Singapore OEMs to scale operations safely and durably.

OEM contract manufacturing medical devices by AMT

AMT acts as a comprehensive partner for clients needing an OEM medical device manufacturer—covering design collaboration, rapid prototyping, tooling, and material sourcing, then moving into PCBA, injection molding, and cleanroom assembly.

AMT’s Positioning as OEM/CM

AMT excels at full assembly contracts and turnkey production, enabling clients to focus on research, sales, and post-market support while outsourcing validation and commercialization.

AMT’s services are expandable, accommodating both prototype volumes and mass production—benefiting startups and established medical entities alike.

Certifications & Compliance

AMT adheres to ISO 9001 and ISO 13485 standards, meeting regulatory and purchaser expectations for medical device manufacturing.

Facilities align to 21 CFR Part 820, supporting FDA-aligned documentation, including device history records and traceability for Class I–III devices.

ISO-class cleanroom manufacturing and sterilization-ready processes minimize contamination risks, helping ensure product safety through scale-up and commercialization.

| Core Capability | Outcome | Standard |

|---|---|---|

| Turnkey production and assembly | Single-source responsibility for product launch and scale | ISO 13485 + 21 CFR 820 |

| Electronics/PCBA integration | Robust assembly plus DFM input | Traceability, device history records |

| Precision injection molding | Repeatable parts via validated tools | PV & material tracking |

| Clean assembly & sterile-ready flows | Reduced contamination risk | ISO cleanrooms + validated sterility |

| Submission support | Submission-ready documentation | DHR & QA procedures |

AMT’s Core Capabilities & Production Solutions

AMT applies specialized equipment and meticulous process controls to craft scalable, reliable production solutions for Singapore and the region. They align materials, validation, and training to device-specific needs while maintaining competitive unit costs.

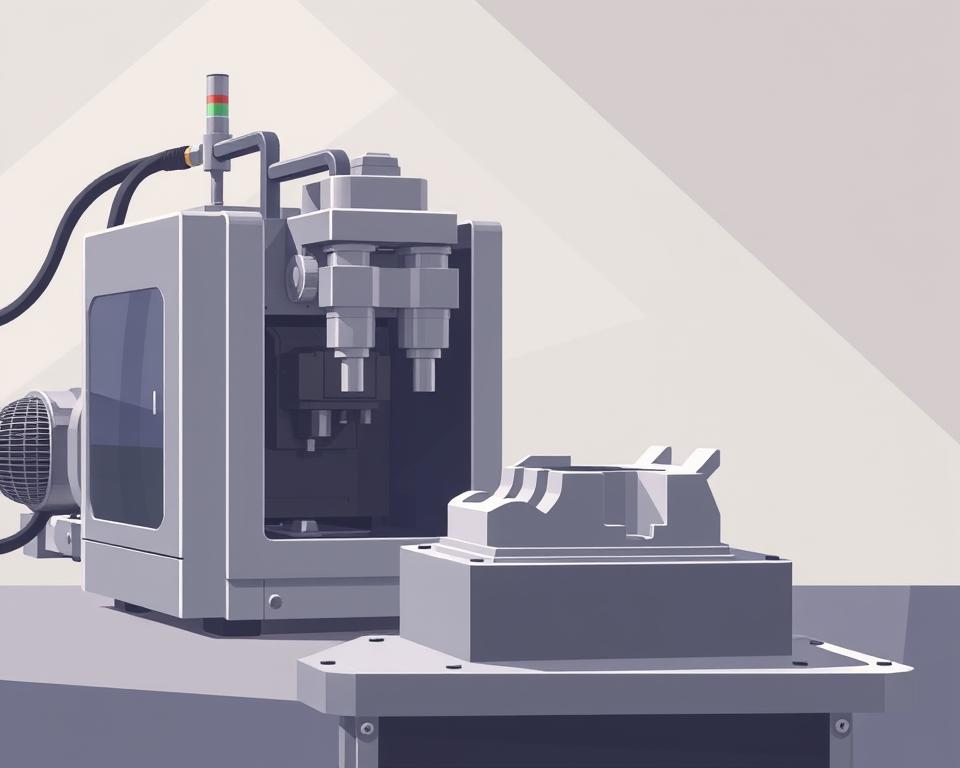

AMT excels in precision injection molding for high-volume parts—housings, brackets, and connectors requiring sterilization. The workflow covers tooling design, mold fabrication, and precision molding to deliver tight-tolerance, biocompatible parts.

Injection molding is key to repeatability and cost reduction at scale. AMT’s tooling capabilities include multi-cavity tools and insert molding, important for overmolded features that fit neatly into automated assembly lines.

AMT’s electronics workstreams cater to PCBA medical devices with DFM support and component sourcing—covering both SMT and through-hole—tailored to medical industry expectations.

Validation for PCBA medical devices includes rigorous inspection and traceability: test fixtures, in-circuit testing, and burn-in cycles to ensure reliability for monitoring, telehealth, and therapy applications.

For cleanroom assembly, AMT maintains ISO-class environments, managing particulates and microbes. Processes include catheter assembly and handling sensitive electromechanical subassemblies, with contamination risks mitigated throughout final integration.

AMT’s product integration services span electromechanical assembly, final functional testing, packaging, and pre-sterilization prep. With device history records, serialized traceability, and detailed work instructions, they bolster compliance and continuous optimization.

This capability suite creates a complete, customized pathway that aligns molded components, PCBA devices, and cleanroom assembly—accelerating scale-up timelines to meet client requirements.

Engineering & Prototyping at AMT

AMT combines engineering expertise with practical process development to advance device makers from idea to production efficiently. Early feedback minimizes risk and speeds validation—keeping development on schedule for Singapore and nearby markets.

Collaborative design-for-manufacture and NPI support

AMT works closely with client design teams to streamline assemblies, cut part counts, and enhance serviceability—making devices easier to manufacture and scale.

NPI support covers engineering reviews, tooling design, and process flow development. AMT creates work instructions and operator training to ensure consistent outcomes and minimize costly redesigns.

Prototype-to-Scale Transfer

Rapid prototyping enables functional testing prior to full tooling. AMT conducts iterative prototypes to refine materials, tolerances, and layouts—shortening development time and confirming feasibility early.

When prototypes meet targets, AMT moves into structured transfer: process validation (including IQ/OQ/PQ as needed), pilot runs, and detailed planning—securing a smooth transition from clinical to commercial production.

Efficient project management drives staged transfers, reducing interruptions and aligning regulatory documentation with growth.

Quality Systems and Regulatory Support

AMT prioritizes safety and compliance throughout production—integrating procedures, training, and electronic oversight to lower defects and speed regulatory progress for Singapore and global markets.

Quality Management + Traceability

Aligned with ISO 13485 contract manufacturing and ISO 9001, AMT’s QMS covers document control, supplier assessment, incoming inspection, and corrective actions. eDHR and mandatory process routing ensure lot control to meet device traceability requirements.

Standardized work and operator training enable consistent quality. Lean and Six Sigma boost efficiency and maintain competitive pricing. Supplier evaluations and material checks ensure end-to-end traceability.

Regulatory Navigation & FDA

AMT supports regulatory documents and keeps validation evidence to facilitate audits and approvals. Operations align to 21 CFR Part 820 for applicable devices, with meticulous records across Class I–III. Internal audit readiness and expert coordination assist clients during inspections and market entry.

| Quality Element | Implementation | OEM Benefit |

|---|---|---|

| QMS Standards | ISO 13485 contract manufacturing and ISO 9001 alignment | Simpler audits; wider market access |

| Lot/Serial Traceability | eDHR, lot control, component tracking | Rapid issue resolution |

| Production Controls | Forced process routing and standardized work | Reduced defects and consistent yields |

| Submissions | Regulatory support FDA documentation and validation packs | Improved submission readiness and inspection response |

| Audit Readiness | Internal + supplier audits | Reduced risk |

Sourcing Advantages and Supply Resilience

AMT enhances supply chain resilience by combining local procurement with a curated global network—maintaining optimized inventory and access to medical-grade components for diverse assemblies. This approach reduces single-source dependence and delivers predictable lead times across Singapore and neighboring markets.

A dedicated team focuses on material sourcing and BOM cost management. Through supplier qualification, vendor audits, and alternate sourcing, AMT maintains quality for critical components. Refined BOMs and consolidated buys reduce total landed cost for OEMs.

Cost-Focused Sourcing

AMT uses design-for-cost inputs, standardized parts, and waste-reducing process enhancements to ensure competitive unit pricing. Consolidated contracts and negotiated freight reduce overheads—boosting predictability and cost-efficiency.

Flexible Manufacturing Capacity

AMT excels in scalable manufacturing via adaptable capacity planning—BTO, build-to-stock, and configure-to-order models—giving OEMs inventory optimization and faster response to demand changes with full traceability.

Prototype-to-mass production transitions are streamlined by validated protocols and pilot runs. Tiered CM practices maintain quality and compliance during ramp, supporting reliability for rapid market access.

| Issue | How AMT Responds | Benefit |

|---|---|---|

| Supplier concentration | Vendor audits and alternate sourcing | Improved continuity and fewer production disruptions |

| Rising component costs | BOM optimization + consolidation | Lower TLC |

| Fluctuating demand | Flexible models + planning | Fewer stockouts |

| Scale-up risk | Pilots + validated transfers | Predictable scale-up |

Case studies and success stories showcasing AMT’s expertise

AMT is known for emergency builds and complex product transfers. Collaborations with OEMs and care teams translate into tangible results—turning prototypes into dependable production lines for hospitals and distributors.

A telehealth ventilator program showcases AMT’s Tier-2 role: sourcing, injection-molded parts, PCBA, and final assembly for infectious-disease wards—demanding quick validation, sterile-ready components, and strict lot traceability.

Working closely with the OEM, AMT met functional and regulatory requirements. Thanks to stringent quality control and scalable capacity, AMT kept up with rising hospital demand—delivering a predictable, auditable production process.

Across clinical-to-commercial transfers, AMT shows strong NPI and transition expertise—pilot runs and rigorous validation moving devices from small batches to volume in line with ISO 1345 and FDA guidance.

OEMs see reduced lead times, lower investment, and transparent cost structures—highlighting why many medical device case studies choose AMT to reduce production risk and speed market entry.

These programs establish a foundation for future cooperation—engineered solutions, complete regulatory documentation, and consistent processes that support long-term product success.

What’s Next and How AMT Prepares

In Singapore, medtech growth is fueled by telehealth, remote diagnostics, and chronic-disease solutions. Aging demographics and more advanced, smaller devices push outsourcing toward skilled CMs—underscoring the value of all-inclusive development partners.

Industry outlook and growth sectors

Cardiovascular and orthopedic devices are set for significant growth. Telehealth and point-of-care diagnostics increase production of components and finished goods. Manufacturers that ramp fast and navigate regulations will be in high demand.

OEMs will look for strategic CM relationships akin to CDMOs—favoring partners that pair end-to-end development with robust supply chain management.

Advanced Manufacturing & Digitalization

Industry 4.0 will reshape plants via automation, robotics, and advanced systems—driving higher efficiency and consistency. Digital tools like Electronic Device History Records enhance product safety and audit performance.

Supply-chain digitalization sharpens forecasting and QA—creating efficient, risk-mitigated distribution. CMs that modernize stand out on delivery speed and regulatory adherence.

| Shift | Impact on OEMs | AMT Response |

|---|---|---|

| Telehealth and diagnostics growth | Volume + speed demands | Prototyping-to-scale pathways |

| Automation & Robotics | Quicker validation cycles | MES-ready processes, machine vision, automation-ready cells |

| Digital supply networks | Proactive risk control | Integrated sourcing strategies, digital inventory and forecasting |

| Regulatory pressure and documentation | More evidence + tracking | eDHR + strong QMS |

| Demand for CDMO-style partnerships | Need for single-vendor end-to-end services | Turnkey medical device development services, DFM and NPI support |

AMT has expanded capability with advanced machinery, cleanrooms, and PCBA lines, ready to incorporate automation and sophisticated quality systems—placing AMT at the forefront of complex device production and compliance.

The Final Word

The global medical device market is expanding quickly, pushing Singapore OEMs toward specialist partners. By outsourcing, they lower initial investment and get to market faster. AMT specializes in oem contract manufacturing for medical devices—covering precision injection molding to cleanroom assembly.

AMT backs its offering with strong quality systems and regulatory adherence—minimizing compliance risk. Solid sourcing strategies and adaptable capacity lower supply-chain disruption risk. For teams seeking a contract manufacturing partner, AMT is a compelling choice—pairing detailed traceability, proven processes, and case results such as the telehealth ventilator initiative.

For developers moving from prototype to mass production, the fit-for-purpose partner is crucial. Beyond certifications, look for deep engineering expertise and scalable production capability. Choosing AMT for contract manufacturing can significantly reduce capital costs, accelerate development, and improve the likelihood of successful market entry in Singapore and beyond.